The Grocery Stores Scales are called the beam balance scales. that is the instrument for the weighing the grocery items are used since many years and believed the first measuring instrument. It has pivoted horizontal level of equal length arm. The each arm is called a beam. There are pair of weighing pan, and whole system is called scale.

The unknown mass is placed in one pan and standard masses are added to the other pan till the equilibrium of the beam.

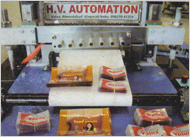

The pendulum balance scales are seen somewhere in the market. But nowadays the awareness of the customers is increased, so the merchants are being advance accepting the digital scales, which shows weight in digit and more accurately.

If one want to weigh a heavy things like trucks, cars, the different systems should apply. The scales cannot be used for that purpose. So for weighing the trucks, the system used, is called Truck Load Weighbridge.

The weighing bridge for the truck are available with steel deck and concrete deck The weigh bridges are specially designed for the light commercial to extreme heavy duty. So the weight of loaded and unloaded both type of the trucks can be measured by the bridge.

The weigh bridge are equipped with the load cells that connect to an electronic equipment to totalize the input of the sensors. At many weigh bridge the facility to connect with a personal computer is given.

The unknown mass is placed in one pan and standard masses are added to the other pan till the equilibrium of the beam.

The pendulum balance scales are seen somewhere in the market. But nowadays the awareness of the customers is increased, so the merchants are being advance accepting the digital scales, which shows weight in digit and more accurately.

If one want to weigh a heavy things like trucks, cars, the different systems should apply. The scales cannot be used for that purpose. So for weighing the trucks, the system used, is called Truck Load Weighbridge.

The weighing bridge for the truck are available with steel deck and concrete deck The weigh bridges are specially designed for the light commercial to extreme heavy duty. So the weight of loaded and unloaded both type of the trucks can be measured by the bridge.

The weigh bridge are equipped with the load cells that connect to an electronic equipment to totalize the input of the sensors. At many weigh bridge the facility to connect with a personal computer is given.